The only other option for specialized machinery besides custom machines are retrofitting existing machines; machines can be changed and adjusted to become more cost effective or to perform new operations. By its very definition, there are no typical custom machines. However, certain machines are customized with more frequency than others such as lathes, mills, hydraulic presses, shears, press brakes, MIG or TIG welders, drill presses, band saws, magnetic drills and other machines. Read More…

A recognized leader in automated assembly products. Stay competitive with Dixon's robotic screwdrivers, auto-fed screw & nut drivers, auto-fed part placers, parts feeding systems & assembly cells, including robotic assembly & vision. Every Dixon product is manufactured to assure accuracy & dependability for repetitive assembly. Dixon supports Machine Integrators with assembly products & stations. ...

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

Advent design has been in business for over 35 years providing custom automation solutions, engineering, integration solutions and machine safety services. Contact us today to discuss your project needs and see how we can help you achieve your goals.

Since 1982, Isotech has been a leader in the automation equipment industry. You can trust the accuracy of our solutions. Our experts at Isotech are always available to assist you with your needs. Feel free to contact us today to learn more information!

Del-Tron Precision is your one-stop shop for ball & crossed roller slides, multi-axis positioning and motor-ready lead screw stages, air actuators, recirculating slide guides and crossed roller rail sets. Custom linear slides are available.

More Custom Machinery Manufacturers

Custom Machinery: Tailored Solutions for Industrial Automation and Efficiency

Custom machinery, also known as bespoke machinery or specialized industrial equipment, refers to machines precisely engineered and manufactured to meet the unique requirements of a specific process, product, or industrial facility. Unlike off-the-shelf manufacturing equipment, custom machines are designed for adaptability, scalability, and optimized performance, providing a significant competitive edge to enterprises across diverse sectors. Whether you’re seeking to boost throughput, automate complex assembly, or integrate robotics and smart technologies, custom machinery offers the flexibility to achieve your operational goals.

With the rise of Industry 4.0 and the growing demand for advanced manufacturing technologies, the ability to specify every aspect of your machinery—from power source, capacity, and operating speed to blade size, bit diameter, length, width, height, and control systems—means you can create industrial automation equipment that is truly fit-for-purpose. Whether you operate in automotive, electronics, food processing, or pharmaceuticals, custom machine solutions can be tailored to your unique requirements.

Why Invest in Custom Machinery?

Are you searching for ways to increase productivity, reduce operational costs, or solve a unique manufacturing challenge? Custom machinery offers a targeted approach, enabling businesses to automate processes, integrate robotics, and streamline complex manufacturing or assembly operations. The decision to invest in custom automation equipment or build-to-spec machines is often driven by several business-critical needs:

- Enhanced operational efficiency and increased throughput

- Consistent product quality and process repeatability

- Reduced labor costs and minimized human error

- Seamless integration with existing automation systems

- Compliance with industry-specific safety, regulatory, or quality standards

- Adaptation to unique production environments, restricted floor space, or specialized workflows

- Future scalability through modular design and upgrade paths

- Support for digital transformation and smart manufacturing initiatives

Custom machinery is a strategic investment for any industrial company, especially those operating in sectors where standard machines fall short. Whether for robotics integration, automated assembly systems, or niche manufacturing processes, custom industrial machines are indispensable in industries such as aerospace, agriculture, automotive, computer, electrical, electronics, fiber optics, food and beverage, jewelry, medical devices, plumbing, semiconductor, textile, telecommunications, and many more.

Industries and Applications of Custom Machinery

Custom industrial machinery is a driving force behind innovation, productivity, and quality in a wide array of industries. Discover how tailored equipment solutions are transforming operations:

- Aerospace: Precision assembly systems, engine component fabrication, automated drilling stations, and quality assurance machines for critical parts

- Automotive: Robotic welding cells, automated inspection, material handling equipment, high-speed assembly lines, and component testing stations

- Medical Devices: High-speed assembly lines for medical disposables, pharmaceutical packaging, diagnostic machinery, and automated cleanroom systems

- Electronics & Semiconductors: PCB assembly automation, microchip handling robots, cleanroom-compliant pick-and-place machines, and automated optical inspection (AOI) systems

- Food & Beverage: Custom filling, packaging, sorting, and conveyance systems meeting FDA/USDA standards, along with hygienic design features

- Agriculture: Seed sorting machines, automated harvesting systems, crop processing machinery, and smart irrigation equipment

- Textiles & Apparel: Automated fabric cutting, stitching, folding, and quality inspection machines for high-volume production

- Telecommunications: Fiber optic cable assembly, connector manufacturing, precision spooling, and automated cable testing devices

- General Manufacturing: Palletizing solutions, custom material handling, automated machining centers, and process-specific assembly systems

Are you interested in a specific industry application or want to see how customized automation could improve your line? Contact us to discuss your custom machinery needs or request case studies from your sector.

Custom Machinery Design and Engineering Process

Are you wondering, How is custom machinery designed and built? The journey from concept to commissioning is a collaborative and detail-oriented process, essential for delivering equipment that aligns perfectly with your production goals. Here’s what to expect during a typical custom machinery development project:

- Initial Consultation: Engineers and design specialists meet with the client to thoroughly understand technical requirements, production targets, operational constraints, and integration needs. This comprehensive needs assessment ensures all factors—including cycle times, product dimensions, regulatory compliance, and automation level—are considered.

- Concept Development: The design team creates preliminary concepts and presents them to the client, iterating based on feedback to ensure alignment with expectations and industry best practices.

- Detailed Engineering: Upon concept approval, engineering and design departments produce detailed CAD models, mechanical drawings, electrical schematics, and control logic diagrams. Specifications may include custom-fabricated parts, sensors, actuators, and control systems.

- Procurement and Fabrication: Components are sourced or manufactured, including machined parts, fabricated frames, drive systems, control panels, and safety enclosures. Advanced manufacturing techniques such as CNC machining, laser cutting, waterjet cutting, and 3D printing are often utilized for precision and quality.

- Assembly and Integration: The machine is assembled, integrating all mechanical, electrical, pneumatic, and software systems. Specialized modules—such as vision inspection, conveyors, robotic arms, feeder systems, or palletizers—are added as needed for application-specific functionality.

- Testing and Validation: Rigorous testing is conducted to ensure the custom machine meets all functional, safety, and quality requirements. This includes Factory Acceptance Testing (FAT), Site Acceptance Testing (SAT), and validation against performance benchmarks such as speed, accuracy, and uptime.

- Installation, Training, and Support: After approval, the machinery is installed at the client’s facility. Operators and maintenance teams receive comprehensive training, and ongoing support is provided to maximize equipment uptime and long-term reliability.

Effective collaboration between the manufacturer and client is crucial to ensure the machinery meets all expectations. Clear communication and thorough documentation at every stage of the design and engineering process help avoid costly rework and ensure the final product delivers measurable value.

Customization Options and Advanced Features

What options can be customized in industrial machinery? Custom machines can be tailored in countless ways to meet your specific production needs, including:

- Power Source: Electric, pneumatic, hydraulic, or hybrid drive systems—selected based on energy efficiency, force requirements, and control complexity

- Capacity and Throughput: Designed for batch or continuous production, with throughput rates engineered to match client requirements, from low-volume prototyping to high-speed mass production

- Operating Speed: Variable speed controls, high-speed actuation (up to 1000 parts/minute), and servo-driven motion for precision tasks

- Physical Dimensions: Custom width, height, length, footprint, and orientation to fit available space and integrate seamlessly into existing lines or plant layouts

- Tooling and End Effectors: Bespoke grippers, blades, fixtures, robotic end-effectors, and interchangeable tooling for rapid changeover

- Material Handling: Integrated conveyors, rotary tables, feeder bowls, vibratory feeders, pick-and-place modules, and automated palletizing or depalletizing systems

- Automation Level: Options for manual, semi-automated, or fully automated solutions, leveraging advanced PLC and HMI controls for user-friendly operation

- Vision Systems and Quality Control: Machine vision inspection, automated rejection handling, traceability and serialization, and in-line metrology for consistent quality

- Data Integration: Industrial IoT (IIoT) connectivity, MES/ERP system integration, cloud-based monitoring, and predictive maintenance analytics

- Safety Features: Custom guarding, light curtains, emergency stop systems, lockout/tagout provisions, and compliance with OSHA, CE, or other relevant safety directives

Customization often extends to software, data logging, remote diagnostics, and advanced automation features, allowing your industrial machinery to adapt to changing production demands and regulatory requirements. Machines may also incorporate specialty modules such as palletizers, robotic arms, or unique conveyors for continuous, non-standard motion paths.

Key Benefits of Investing in Custom Machinery

Are you weighing the decision between custom machinery and standard equipment? Here are the compelling advantages of investing in custom-built industrial machinery for manufacturers, process engineers, and plant managers:

- Process Optimization: Eliminate workflow bottlenecks and design equipment that precisely fits your manufacturing process

- Increased Productivity: Achieve higher output rates, greater machine uptime, and reduced cycle times through tailored automation

- Improved Quality Control: Ensure product consistency, enable full traceability, and reduce defects with integrated inspection and data logging

- Reduced Labor Costs: Automate repetitive, hazardous, or ergonomically challenging tasks to minimize manual labor and improve worker safety

- Enhanced Flexibility: Modular and scalable machine designs allow for future upgrades, new product lines, or process changes as your business evolves

- Long-Term ROI: While custom machines may have a higher initial cost, they typically deliver a lower total cost of ownership through efficiency gains, minimal downtime, and reduced maintenance

- Competitive Advantage: Proprietary automation solutions can differentiate your business, enabling you to offer unique capabilities or higher-quality products in your market

- Regulatory Compliance: Ensure adherence to sector-specific safety, hygiene, and environmental standards, supporting product certification and market approvals

- Digital Transformation: Support for smart factory initiatives, IIoT integration, and real-time production analytics

Not sure if custom machinery is right for you? Request a complimentary workflow analysis or ROI calculation from our engineering team to see how tailored automation could transform your business.

Use Cases: Real-World Applications of Custom Machinery

Looking for examples of custom machinery in action? Here are a few use cases that showcase the versatility and value of bespoke industrial equipment across different market sectors:

- Robotics Integration in Automotive Manufacturing: Custom robotic cells assembling complex subcomponents, reducing assembly time, improving consistency, and supporting flexible manufacturing systems (FMS)

- Pharmaceutical Packaging Line Automation: High-speed filling and capping machines, capable of handling multiple bottle sizes and formats with rapid changeover, integrated with vision inspection for regulatory compliance

- Electronics PCB Assembly: Machines designed for precise component placement, soldering, and automated functional testing in cleanroom environments

- Textile Cutting Automation: Automated cutting tables with vision-guided blade positioning, ensuring zero-defect garment production and reducing material waste

- Food Industry Palletizing Systems: Custom conveyors and robotic palletizers that handle variable product sizes, packaging types, and high-speed sorting requirements

- Medical Device Assembly: Inline assembly and inspection stations, custom designed to meet FDA and ISO 13485 requirements for medical device quality assurance

- Plastics Manufacturing: Automated injection molding cells with integrated part handling, cooling, and packaging modules for high-volume production

- Wire Harness Assembly: Custom machines for wire cutting, stripping, crimping, and electrical testing, reducing manual labor and improving traceability

Want to see more examples? Browse our library of custom machinery case studies or ask about your specific industry application.

Decision Factors: Choosing the Right Custom Machinery Partner

How do you choose the best custom machinery manufacturer? Selecting a reliable partner is essential to the success of your automation project. Consider the following factors when evaluating potential suppliers and systems integrators:

- Industry Experience: Does the supplier have a proven track record of delivering similar projects in your sector (e.g., automotive, food, electronics)?

- Engineering Expertise: Assess their capabilities in mechanical design, controls engineering, robotics integration, and software development

- Project Management: Look for strong communication, transparent timelines, and the ability to manage complex, multi-phase projects

- Quality Assurance: Inquire about their quality control processes, testing protocols, certifications (such as ISO 9001), and risk mitigation strategies

- After-Sales Support: Ensure the supplier offers comprehensive training, technical support, preventative maintenance programs, and spare parts availability

- References and Case Studies: Request examples of past projects, client testimonials, and documented ROI for similar solutions

- Customization and Innovation: Can they offer modular designs, future upgrade paths, and support for digital technologies such as IIoT?

Ready to start your search? Download our checklist for evaluating custom machinery suppliers or request a quote from our experienced engineering team.

Comparing Custom Machinery vs. Standard Machinery

What are the differences between custom machinery and standard (off-the-shelf) equipment? Here is a side-by-side comparison to help guide your investment decision and support your capital equipment justification process:

| Criteria | Custom Machinery | Standard Machinery |

|---|---|---|

| Design Flexibility | Fully tailored to process requirements | Fixed configurations, limited adaptability |

| Initial Cost | Higher upfront investment | Lower upfront cost |

| Lead Time | Longer – requires engineering and prototyping | Shorter – off-the-shelf availability |

| Integration | Seamless integration with existing lines and processes | May require modification or retrofitting |

| Long-Term ROI | Higher, due to efficiency and reduced downtime | Standard, may require upgrades or replacements |

| Maintenance | Supported by original builders, with custom spare parts and documentation | Standardized support, but less tailored to specific needs |

| Scalability | Modular designs support future expansion and upgrades | Limited scalability; upgrading may require full replacement |

| Compliance | Designed to meet industry-specific safety and regulatory standards | Meets general compliance, may not address unique requirements |

Still unsure which is right for your operation? Contact our team for a tailored cost-benefit analysis.

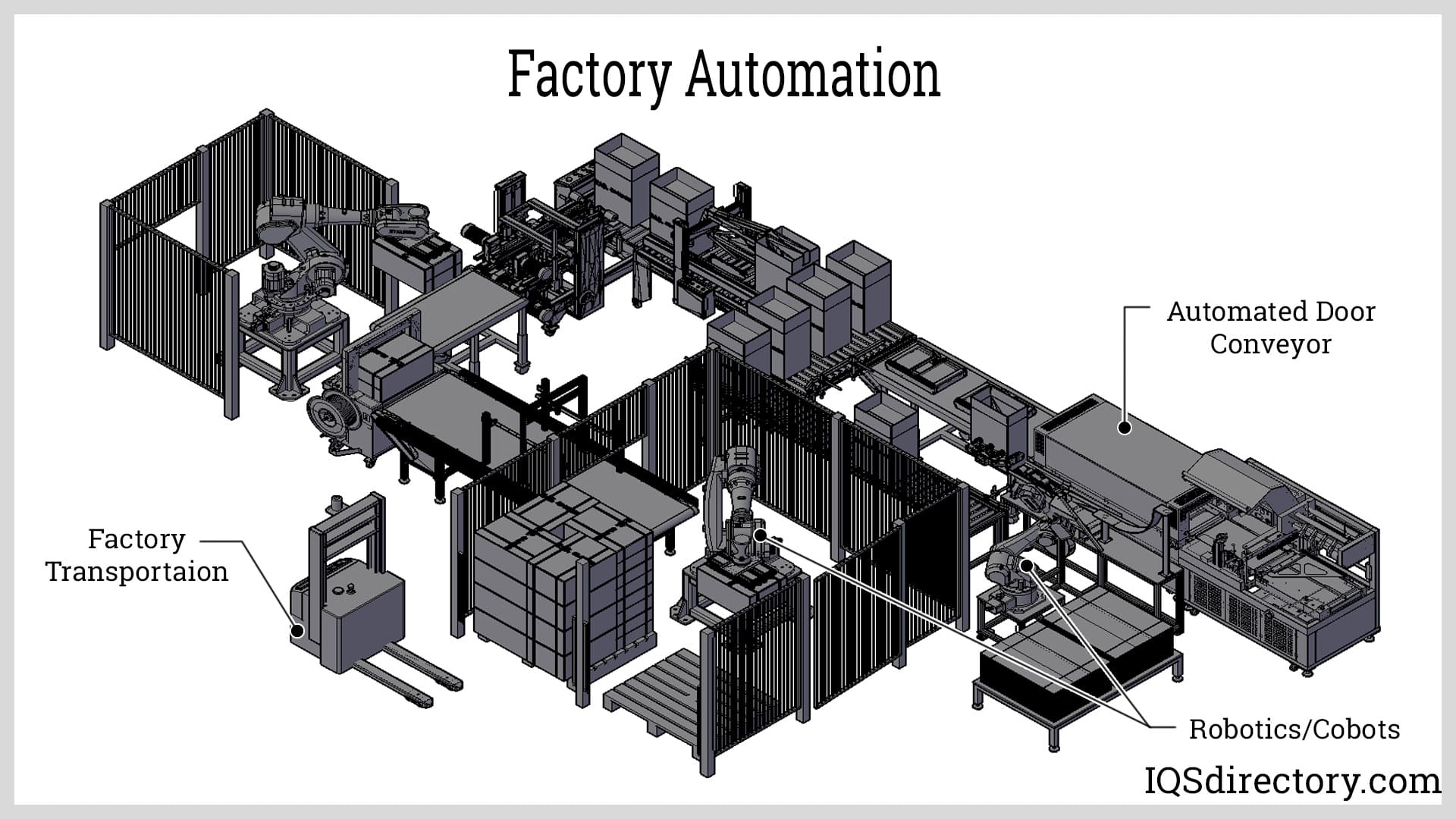

Driving Innovation with Factory Automation Systems

Upgrading to high-speed automation systems can dramatically increase output and efficiency. Factory or manufacturing automation systems are predominantly custom designed because they deliver superior cost effectiveness, labor savings, and product consistency compared to standard solutions. By integrating advanced robotics, machine vision, and smart controls, these systems enable manufacturers to achieve next-level automation.

Factory automation systems, when paired with custom machinery, enable manufacturers to achieve lights-out manufacturing, improve real-time data acquisition, and benefit from predictive maintenance. Whether you need traceability, frequent product changeover, or rigorous quality control, custom automation delivers the scalability and flexibility that modern manufacturers require. From new plant construction to legacy equipment upgrades, custom-engineered systems are the keystone of digital transformation and operational excellence.

Ready to learn more about how factory automation can power your growth? Explore our resources on factory automation or request a consultation with our automation engineers.

Frequently Asked Questions about Custom Machinery

- What is the typical lead time for custom machinery? Lead times vary by complexity, but most projects range from 12 to 36 weeks from concept to installation. Early engagement and clear project scope can help compress timelines.

- Can I retrofit existing equipment with custom modules? Yes, many custom machinery manufacturers specialize in retrofitting and upgrading legacy machines to enhance automation, add new features, or improve safety and compliance.

- Is custom machinery suitable for small production runs? While often used for high-volume manufacturing, custom machines can be economically viable for short runs where precision, flexibility, or unique processes are required, especially in high-mix, low-volume (HMLV) environments.

- How do I ensure the custom machine is future-proof? Work with suppliers who offer modular design, software upgradability, and support for IIoT connectivity and remote diagnostics.

- What ongoing support is available? Leading suppliers offer preventative maintenance contracts, remote troubleshooting, operator training, and rapid spare parts delivery to maximize equipment uptime.

- What industries benefit most from custom machinery? Aerospace, automotive, electronics, medical devices, food and beverage, packaging, textiles, and general manufacturing are just a few of the sectors that rely heavily on bespoke equipment for process optimization and compliance.

Next Steps: How to Start Your Custom Machinery Project

Ready to explore custom machinery solutions for your business? Here’s how to get started:

- Define your production goals, key performance indicators (KPIs), and quality targets

- Review your current workflow, identifying bottlenecks, inefficiencies, and areas for automation

- Gather supporting documentation such as process diagrams, product drawings, safety requirements, and output data

- Engage with an experienced custom machinery manufacturer for an initial consultation and feasibility assessment

- Request a detailed proposal, including concept designs, budgetary pricing, and project timelines

- Evaluate proposals based on technical fit, supplier reputation, and long-term support offerings

For more information about automation system manufacturers, click here or explore our growing collection of resources on factory automation and advanced manufacturing technologies.

Explore More on Custom Machinery and Automation

- What are the latest trends in industrial automation and robotics?

- How does factory automation improve productivity and quality?

- What types of assembly machinery are best for my industry?

- How can I find a trusted automation system manufacturer?

- What factors should I consider before investing in factory automation?

Custom machinery stands as a cornerstone of modern manufacturing, empowering companies to address unique challenges, optimize production, and maintain a sharp competitive edge. By investing in tailored automation solutions, businesses unlock new levels of efficiency, quality, and scalability, meeting the demands of today’s fast-evolving industrial landscape.

Still have questions? Contact us for a free consultation or explore our latest whitepapers on custom automation, digital manufacturing, and smart factory integration.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services