Assembly equipment refers to the individual pieces of assembly machinery that make up an assembly line. The overall function of the equipment in the assembly line is to work together, each machine doing one part of the production before the part being produced passes to the next machine. When a part has been worked on by every machine in the assembly line, it is a finished piece. Read More…

A recognized leader in automated assembly products. Stay competitive with Dixon's robotic screwdrivers, auto-fed screw & nut drivers, auto-fed part placers, parts feeding systems & assembly cells, including robotic assembly & vision. Every Dixon product is manufactured to assure accuracy & dependability for repetitive assembly. Dixon supports Machine Integrators with assembly products & stations. ...

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

Advent design has been in business for over 35 years providing custom automation solutions, engineering, integration solutions and machine safety services. Contact us today to discuss your project needs and see how we can help you achieve your goals.

Since 1982, Isotech has been a leader in the automation equipment industry. You can trust the accuracy of our solutions. Our experts at Isotech are always available to assist you with your needs. Feel free to contact us today to learn more information!

Del-Tron Precision is your one-stop shop for ball & crossed roller slides, multi-axis positioning and motor-ready lead screw stages, air actuators, recirculating slide guides and crossed roller rail sets. Custom linear slides are available.

More Assembly Equipment Manufacturers

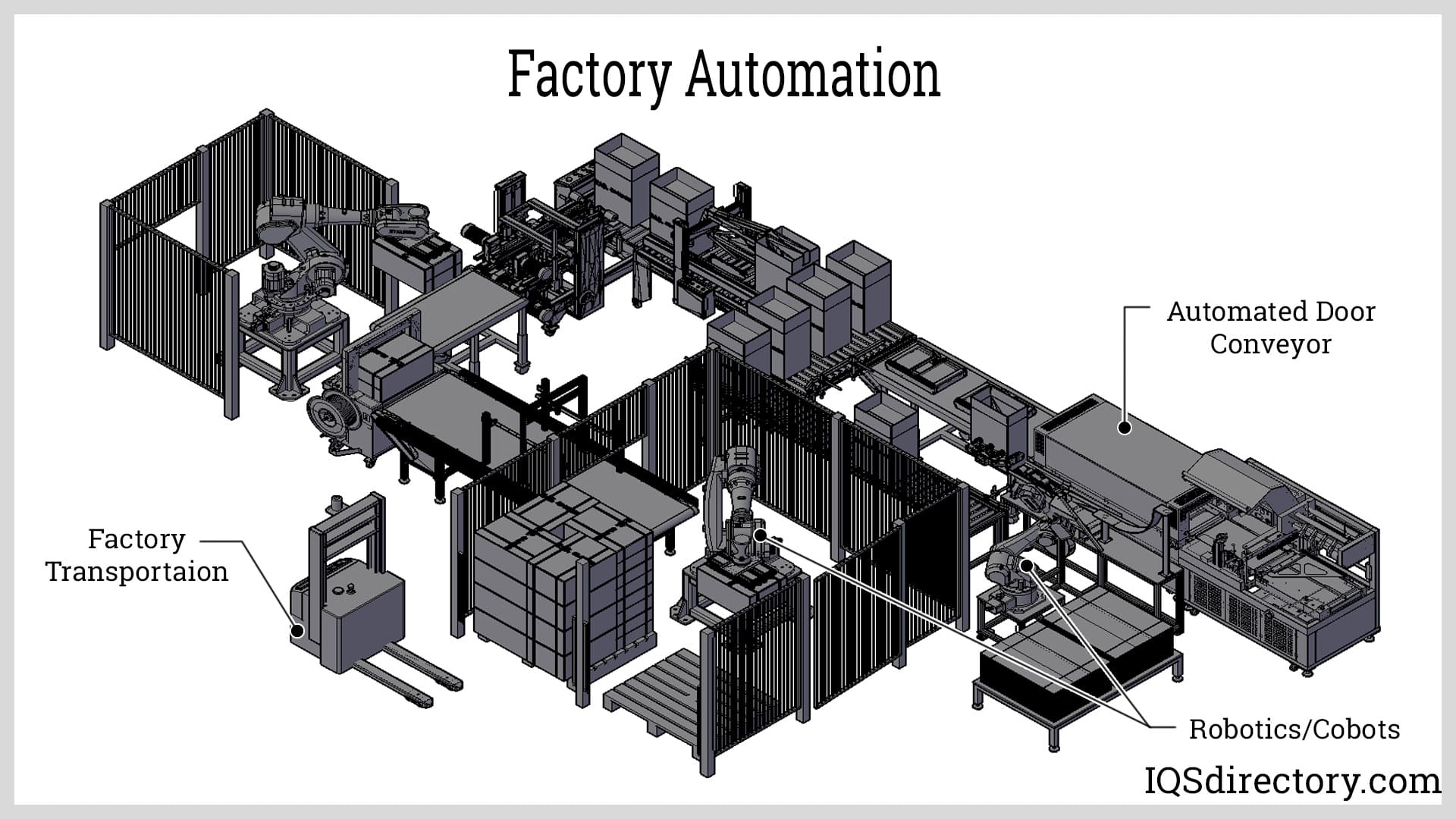

This whole process goes very quickly, since machines do not tire, if they are well maintained, and therefore can run at high speeds for hours. Because assembly equipment is almost always used to mass produce one specific object at a time, the assembly machines themselves are usually custom built. They are also commonly automated systems, which cuts way down on human workers because once the assembly equipment is set up in an assembly line it does all the work mechanically, with very little asked of a human counterpart. In this way, a company installing assembly equipment to mass produce their product will be saving money, since they will not have to hire as many people to watch over the machinery.

Assembly equipment includes computer-controlled robotics, which are capable of producing complicated products. These robots make use of dies, drills, punches and other cutting tools in order to produce different components and parts for a product. A common way that assembly lines get the parts from one step to another is a conveyor belt.

Hoppers or feeders will usually be attached to individual pieces of assembly equipment to supply the required parts in the correct quantities according to the preset software program that usually run the machines. Automated assembly equipment is extremely productive and accurate. They may range in size, depending on their function.

For example, an automotive company is going to require a very large assembly line to produce a car, while a small electronic device, such as a cell-phone, may be produced by a much smaller system. Metallic and plastic materials common in computers and machinery are just as common with assembly equipment since the same benefits apply. The strength and corrosion resistance of stainless steel and aluminum make them popular, while the high melting point and resistance to moisture makes polypropylene a popular piece for machining too.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services